MTBF

Mean Time Between Failure is the predicted elapsed time between inherent failures of a system during operation. MTBF can be calculated as the arithmetic mean (average) time between failures of a system.

The definition of MTBF depends on the definition of what is considered a system failure. For complex, repairable systems, failures are considered to be those out of design conditions which place the system out of service and into a state for repair. Failures which occur that can be left or maintained in an unrepaired condition, and do not place the system out of service, are not considered failures under this definition. In addition, units that are taken down for routine scheduled maintenance or inventory control are not considered within the definition of failure.

Furthermore, MTBF specifically excludes wear-out factors. A fan’s MTBF may be dozens of years but it will invariably wear-out in approximately 3 years. A power supply with an MTBF of 40,000 hours does not mean that the power supply should last for an average of 40,000 hours. According to the theory behind the statistics of confidence intervals, the statistical average becomes the true average as the number of samples increase. An MTBF of 40,000 hours, or 1 year for 1 module, becomes 40,000/2 for two modules and 40,000/4 for four modules.

Finally, MTBF does not directly tell what the expected lifetime of a unit is.

eg: MTBF 174 years for a device, the probability of survival is:

| Time | Probability of Survival |

| 1 year | 99.43% |

| 5 years | 97% |

| 10 years | 94% |

| 20 years | 89% |

| 30 years | 79% |

| ..... | ..... |

| 174 years | 36.8% |

In summary:

- MTBF is not the reliability

- MTBF does not include wear-out

- MTBF is calculated at 40C with 50% electrical stress (for every 10C rise, lifetime is approximately halved)

- MTBF is not accepted by all customers (some regard it as a meaningless number, both absolutely and relatively)

Related Products

-

Low Profile LED Courtesy Light

From: RRP $27.45

$25.50

-

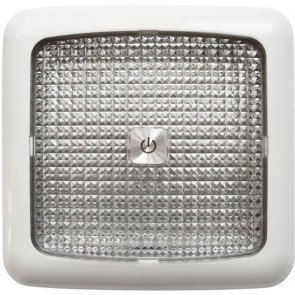

Touch LED Square Ceiling Light

From: RRP $109.45

$107.00